105.11.03 Predictions 2016: contact technology will change connectors

Electroforming contacts is better than stamping and pressing when manufacturing

miniature connectors, writes Hafeez Najumudeen

Whilst semiconductor manufacturers have been halving the size of transistors

roughly every two years, connector manufacturers have been a long way from

keeping pace. One of the reasons is there has been no fundamental change in

contact manufacturing techniques.

Electroforming is a new technique which we at Omron believe overcomes many of

the limitations of stamping and pressing. Not only can smaller, higher quality

and higher performance contacts be manufactured, but the tooling process is much

simpler and cheaper, reducing investment risk and speeding time to market.

What is electroforming?

Electroforming enables high‐precision production of extremely small, thin and

fine patterned contacts. Microfabrication technology allows for considerable

component design flexibility and is also used to meet more exacting needs for

shapes and sizes, since it enables the transfer of a pattern with

submicron‐scale (0.0001 mm) surface roughness accuracy.

Unlike electroplating, electroforming builds thicker, stronger metal layers

which become the actual contact structure.

Electroforming is a metal forming process that forms ultra-thin metal components

through the electroplating process. The components are produced by developing a

layer of metal onto a base form (master). Once the plated layer has been built

up to the desired thickness, the newly formed part is stripped off the master

substrate. Electroforming enables high-precision production of extremely small,

thin and fine patterned parts.

Benefits of EFC

Omron has introduced electroforming technology into the fabrication of the metal

parts of connectors, which were previously formed with presswork. This enabled

forming narrow parts with a high aspect ratio (ratio of thickness and width).

Plates with a width one-third of their thickness have been produced. With

traditional pressed contacts it is difficult to allow the plate width to be less

than the plate thickness.

With electroforming, it is also possible to bend contacts much further.

Traditionally, a plate can be bent to a radius of up to twice the plate

thickness by dynamic mechanical tooling.

Electroforming has achieved a 0.04 mm bend radius by transferring pattern with

static chemical processing. This allows for much more freedom in creating round

shapes, opening new possibilities in component design. This has also allowed

micro slits of 35 microns and holes of 50 microns to be created. These were not

possible with traditional presswork.

With electroformed contact (EFC) technology, burs on cut edges and warping

(undercutting) that are unavoidable with presswork do not occur. A roughness

average (Ra) of as little as 0.1 microns can be achieved with EFC, compared to

typically 3-10 microns with pressed contacts.

In order to reduce the damage to components when attempting to miniaturise them

through press work, soft materials with minimal spring strength have to be used.

However, electroforming can fabricate complex shapes without risk of processing

damage. Therefore, by maximising hardness we can create high spring strength.

Applications of EFC

EFC has already been used to create FPC connectors, battery connectors for smart

phones, slit disks for encoders and miniature probes for semiconductor wafers.

In each case, contacts manufactured with EFC bring greater reliability, improved

performance and further miniaturisation than was possible with press techniques.

For example, in an FPC connector, contact resistance was reduced by 30% from 44

milliohms to 34 milliohms.

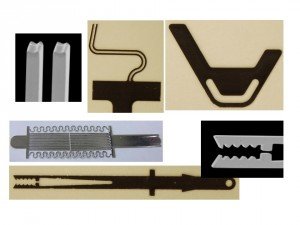

Figure 1: smartphone connector

In smartphone battery connectors (Figure 1), electroformed contacts with

microfabrication achieve a 2 mm pitch and 2.6 mm depth. This compares to a

typical pitch of 2.5 mm and 4 to 5.4 mm depth for pogo pin or pressure style

contacts. While smaller in size, the electroformed contacts are actually less

prone to mechanical fatigue and more shock resistant. Resistance to momentary

power interruptions due to drop impact and repeated vibrations was improved by

30%.

Omron has used electroforming technology in the XD2B line of battery connectors.

This compares to a typical pitch of 2.5 mm and 4 to 5.4 mm depth for pogo pin or

pressure style contacts.

Semiconductor probes

An early area where EFC contacts are already establishing a lead is probe pins

for semiconductors. In recent years, packaging density has been increasing for

surface mount ICs, LCDs, fine-pitch glass substrates, and other electronic

components. This has allowed such components to incorporate more and more

sophisticated functions in electronic equipment.

At the same time, these electronic components have a very large number of pins

and electrode pads, and they are laid out very close to each other on a PCB.

Inspection of electronic components uses a probe pin. Such high-density devices

require inspection of many areas, so multiple probe pins must be placed with a

very small spacing between each. The package unit pitch for recent devices is

only 0.4 to 0.5 mm. In a few years, it is expected to be 0.3 mm or less.

A probe pin is a slender pin-like part that is used to read electric signals

from minute test points when measuring the electrical characteristics of ICs and

other electronic parts. It is a key part that is essential in the test sockets

that hold the ICs in the inspection devices and the probe cards that are built

into the inspection devices.

Using EFC an entirely new style of pin has been created, combining four

components (upper and lower plungers, spring and conductive path) into one. They

have a flat structure which enables placement of pins at any angle, thus making

it easier to reduce pitch compared to a conventional cylindrical probe pin.

The versatility of electroforming technology enables a single component to

incorporate a spring section to provide contact force and durability, and a

barrel section that turns on power when it fits the plunger, separate from each

other. No electricity flows through the miniaturised spring section, thus

solving such problems as excessive temperature rise, the spring section’s

disconnection, and unstable resistance.

Electroformed contacts come in all shapes and sizes

Since there is no need for costly investment in press dies and other equipment,

as well as the time-consuming die-making process for prototyping and mass

production of probe pins, specific demands for customised non-standard

specifications can be satisfied speedily.

Omron has produced flat probes of 60 microns thickness, and sockets of 150

micron pitch can be assembled. EFC probes can also be very robust. The larger

0.6 mm diameter outer spring type can handle up to 2A. To assemble these tiny

contacts, a special air tweezer tool has been created.

Semiconductor probes are a specialist area of the connector market, but the way

in which EFC has overcome the limitations of press technology is illustrative.

EFC has the potential to transform the connector market (figure 2), enabling the

faster manufacture of prototypes, making smaller production runs economic, and

improving the performance of connectors as well as reducing size. Most of all,

it can create new shapes and styles of connector that we have hardly begun to

imagine.

Hafeez Najumudeen is product marketing manager, Omron Electronic Components

Europe

Article Source:http://www.electronicsweekly.com/news/predictions-2016-contact-technology-will-change-connectors-2016-01/